Shoe Lasts and Metrology

Most shoes are made to a last. This is a foot model with dimensions and shape similar to the anatomical foot but sufficiently different to not be exact. Shoe fit and to some extent the last influences its durability.

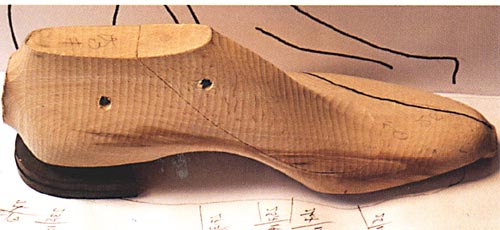

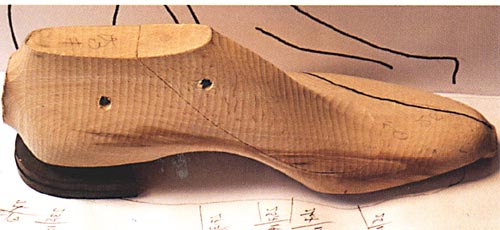

Traditionally before mass production, the original shoemaker started the process by taking a footprint outline of the sole. He whittled or chiselled a wooden last from the print. A last ( 'laest', Old English meaning footprint) was traditionally made from wood but are now available now in metal or plastic. They are complex structures made from many measurements (statistically determined). Lasts are not the same size and dimensions of the anatomical foot but instead an abstract form with specific functions. It is usually deeper in the midfoot region, has a sharp 'feather edge' where the upper surface meets the sole, is clipped in along the topline (around the ankle) and is flaired over and extended in the toe region. This provides shape, which applies appropriate tension when the shoe distorts to contain the loaded foot. Lasts provides a working surface on which flat leather components can be given plastic form. The physical dimensions accommodate the foot during activity and the last contains contemporary fashion and styles such as toe shape. To allow the last to be removed from the shoe they are often hinged around the instep. Shoe lasts are not made to resemble feet but instead to suit the shoe manufacture. Modern lasts are totally unlike the foot with the sole of the last, flat in order to assist in manufacture. Shoe making was classified under three headings: turned shoes, welted shoes and through-seam shoes.

Turned shoe

The turned shoe is made inside out with only an outset sole between the foot and the ground. The upper and soles are very flexible. The last is designed in a single size and then a set is made in the range of sizes and widths in which shoes are to be manufactured. Marked sizes will vary slightly from one manufacturer to another. No longer a popular technique.

Welted Shoes

Any construction using a welting, either as an intrigal part of the construction or simply for imitative effect.

Through Seam Shoes

Anthropometry

Studies show over 90% of people have different sized

feet. Despite feet being the same length other dimensions vary with the

individual foot. Activity of the foot will also change the shape of

identical feet in accordance with the structure and function of the

appendage. The idea of a perfect fit is not a reality. Because distribution

or proportions of foot mass differ with individuals, which mean linear

measurement such as length and breadth of the foot alone, are inadequate. It

is important shoemakers consider mass and volume of feet if an exact fit is

to be afforded. To ensure a best fit, measurements are taken at strategic

locations and the shoemaker uses both linear as well volume measurement to

construct a shoe. The modern last is made in three dimensions although it is

not a direct replica of the foot. Instead it is made with production

requirements, in mind. The lastmaker may take up to 35 measurements before

the model last can be made. A shoe fitter may concentrate on length, ball

width, heel, topline, arch and instep. The shoe is expected to wear well,

feel well, keep its shape with wear, retain its style character, tread

properly, allow for reasonable foot freedom, maintain both foot and shoe

balance, remain structurally intact. These features are not always dependent

on the quality of materials or components, or the manufacturing process. The

design and multiple dimensions of the last provide the basis for the above.

Features built into a last include:

Measurements

The majority of measurements are volume rather than the traditional length and width associated with shoe fit.

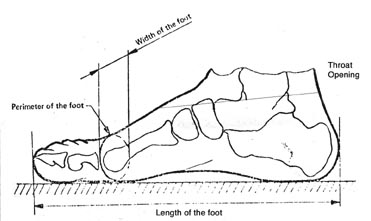

Throat opening

The distance from the vamp point to the back seam tuck.

Length

The length measurement of the foot from the back of the heel to the tip of the longest toe.

Foot Girth

There are four girth and circumference measurements taken

on a last. These are the ball, waist, instep and heel (back of heel to

instep). Measurement requires careful assessment of the foot, which cannot

be accomplished with the same precision as linear measurements. The modern

last maker uses precision instruments to determine girth but the old

shoemakers used the hand span to this same effect.

Ball girth This is the girth measurement around the ball of the last to determine the width and volume allowance inside the shoe.

Waist girth The girth at the waist on the last.

Instep girth The circumference around the foot at the instep.

Heel girth The distance around the foot from the rear base of the heel to the top of the instep.

Recede Toe

This is the part of the last, which projects beyond the tip of the toes forming the rounded contour of the front of the shoe. A tapering recede such as in todays sharp shoes increases the overall length of the shoe. In a poorly designed last the recede may encroach on the toes increasing tension on the ends of the toes. This may be referred to as tight lasting.

Heel-to-ball

This dictates the position of the hinge of the forefoot (metatarsal phalangeal joints) and the widest part of the shoe (across the metatarsal heads).

Toe Spring

This describes the elevation of the undersurface of the sole at the toe to give a slight rocker effect to the shoe. The amount of toe spring (built into the last) depends on the shoe style, sole thickness and heel height. This is built into the last design and compensates for the stiffness of the footwear and provided a stress free take off into propulsion. The more rigid the soling material the greater the toe spring. Many shoes will also display a slight heel spring.

Tread

This describes the width across the sole under the ball of the last and it should correspond to the dimension of the feet. The tread point on the last represents the bottom forepart just behind the ball and in contact with the base plane.

Flare

This describes the curve or contour of the last. The swing is determined by the position of the forepart when the last is bisected longitudinally forwards from the centre of the heel arc. With In inflare lasts there is an inward medial swing to the forepart and most modern shoes are made on an inflare last (banana last) because it is thought shoes are more comfortable. An outflare last describes the opposite with the swing lying to the lateral side of the forepart. Sometimes used in bespoke footwear for infants with diagnosed foot development problems. Straights last describe neither an inflare or outflare preference. The long axis of the last when drawn through the bisection of the heel curve describes two equal longitudinal halves. The normal foot has a straight axis and hence straight lasted shoes can be worn on either foot. Prior to the introduction of machinery to make heeled shoes it was common to have shoe made with a straight flare until the turn of the twentieth century.